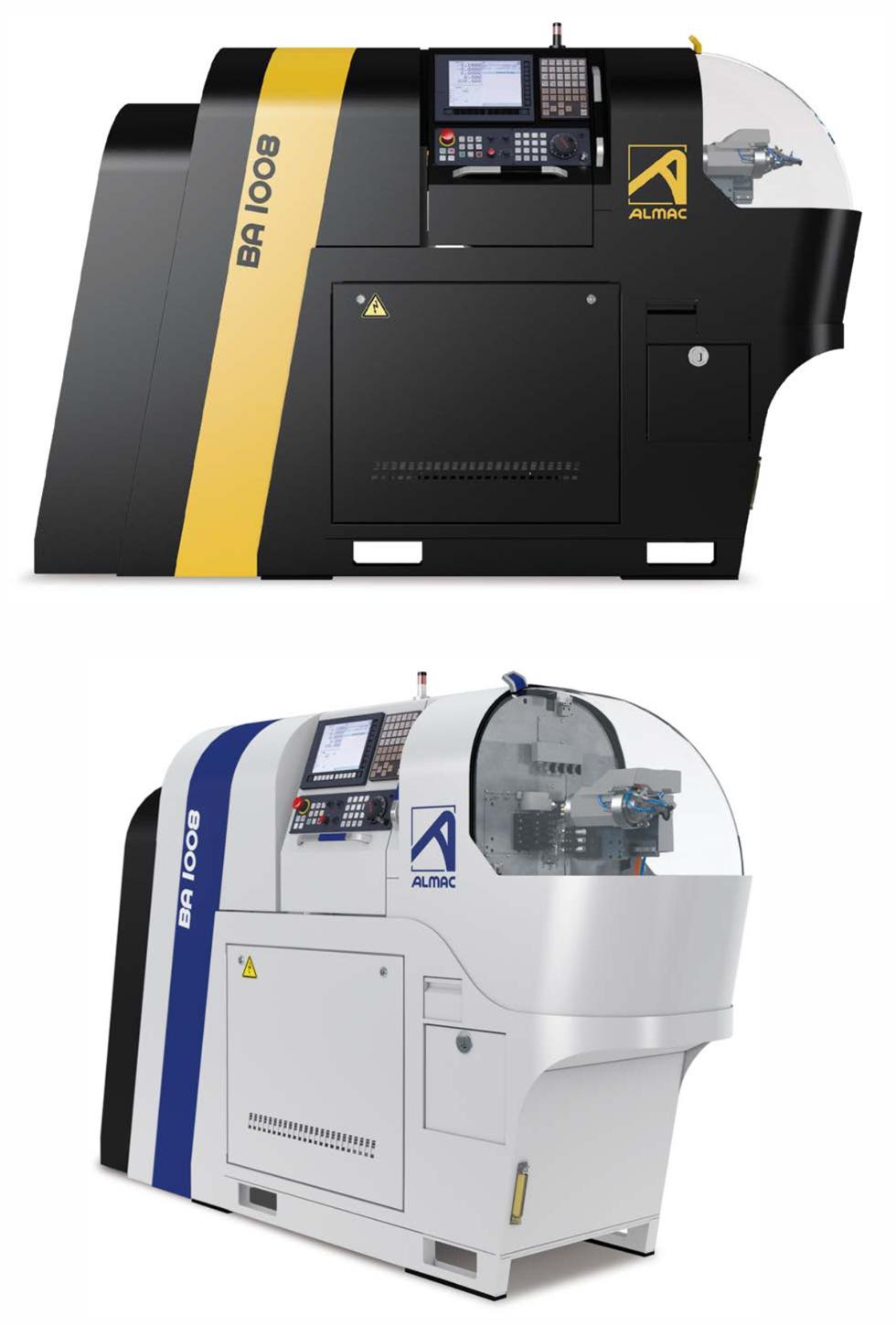

The ultra-compact bar miller born in watchmaking territory

The BA 1008 is fed with bars via the machine, using a divider system which allows workpieces up to a diameter of 16 mm to be loaded. Positioned machining operations and interpolation between the tool systems and the workpiece are easily possible. With 4 frontal spindles, 3 lateral spindles and 2 secondary operation spindles, the BA 1008 is well equipped to service Almac's trademark industry: watchmaking.

- Benefits :

- Ergonomics based on the famous SwissNano from Tornos

- High productivity

- Reduced dimensions

- Excellent value for money

- Types of workpiece :

- Dial components

- Appliques

- Settings

- Windows

- Movement and exterior components.

Unique performance

Designed for milling complex parts from bar stock, the BA 1008 machine is equipped with 4 front spindles, 3 lateral spindles and 2 counter-operation spindles. This multi-spindle technology ensures it can offer the highest productivity. A divider system is used to load workpieces up to a diameter of 16 mm.

Ergonomics

The excellent 180° accessibility of the highly ergonomic machining area, combined with the small footprint of the BA 1008, simplifies the operator's work, in terms of both safety and comfort and access to mechanical areas during setup.

| Technical specifications | BA 1008 |

| Axes | 6 linear + 1 C axis axes |

| Max bar diameter | 16 mm |

| Frontal spindles | 4 spindles 12, 28 or 80,000 (ER11 collets) rpm |

| Lateral spindles | 3 spindles 12, 28 or 80,000 (ER11 collets) rpm |

| Counter-operations | 2 spindles 12, 28 or 80,000 (ER11 collets) rpm |

| Parting | 1 spindle |

| Dimensions L x W x H | 2400 x 650 x 1600 mm |